Product Description

SALES (804) 318-3686

OCCHIO ZEPHYR ESR-C

Developed for the coffee industry by a

team of specialized engineers at Occhio

Measures particle size , shape,and color for:

Coffee Beans

Ground Coffee

Instant Coffee

DYNAMIC PARTICLE CHARACTERIZATION WITH AI, AND COLOR DETECTION

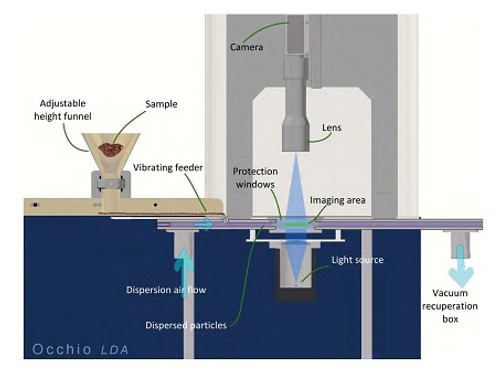

SAMPLE TYPE: FREE FLOWING GRANULARS AND BULK MATERIALS

THAT DISPERSE NATURALLY WITH GRAVITY

APPLICATION RANGE 30 MICRON - 3 CM

FINE AGGREGATE CHARACTERIZATION-

Occhios' proprietary algorithm for measuring asperities, combined with AI, and color detection,

allows for virtual sorting of product defects in coffee, cacao, and other granulars

REPLACE SIEVE ANALYSIS-

Unlike laser diffraction, digital imaging devices can actually correlate with, and replace sieve analysis.

STUDY PRODUCT FLOW PROPERTIES-

Shape parameters like circularity, length, and width, provide valuable information in flow dynamics.

MEASURE PARTICLE ABRASIVE QUALITIES-

The ESR can measure the shape of asperities on a particle, which correlate to abrasion performance.

VALIDATE / SUPPLEMENT LASER DIFFRACTION RESULTS

FINE AGGREGATE CHARACTERIZATION-

Occhios' proprietary algorithm for measuring asperities, correlates with manual angularity measurements

The ESR-C Particle Characterization Analyzer from Occhio Zephyr revolutionizes the way the coffee industry measures and analyzes particle characteristics. Engineered by a dedicated team of specialists, this cutting-edge instrument ensures unparalleled accuracy in assessing particle size, shape, and color, making it an essential addition for professionals committed to quality assurance and control.

Designed specifically for free-flowing granular materials such as coffee beans, ground coffee, and instant coffee, the ESR-C offers dynamic particle characterization using advanced artificial intelligence and integrated color detection. This innovative device enables users to gain comprehensive insights into their products, ensuring consistency and quality will meet even the highest standards.

- Versatile measurement range from 30 microns to 3 cm, ideal for various granular types.

- Proprietary algorithm for precise fine aggregate characterization and virtual sorting of product defects.

- Ability to replace traditional sieve analysis with advanced digital imaging analysis for enhanced accuracy.

- Measure key flow properties including circularity, length, and width for improved product handling.

- Assess particle abrasive qualities by analyzing the shape of surface asperities, directly relating to performance.

- Validation and supplementation of laser diffraction results, ensuring robust quality analysis.

With the ESR-C Particle Characterization Analyzer, elevate your analytical processes and achieve the accuracy your operations demand. Experience the power of cutting-edge technology in your quality assurance practices today.